Dynamic Recrystallization (DRX) Simulations with Built-in and User-defined Models

Reference Folder: $Pandat_Installation_Folder\Pandat 2024 Examples\PanEvolution\Grain_Recrystallization\Physical\

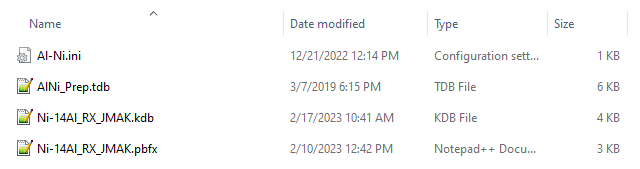

In order to run a recrystallization simulation, four files are needed as shown in Figure 1: 1) “Al-Ni.tdb” – a Ni-Al binary thermodynamic and mobility database; 2) “Ni-14Al_RX_FA_DRX.kdb” – a kdb file for kinetic models and parameters; 3) “Al-Ni.ini” – a file to define the initial grain structure. The initial grain size (radius) is set to 25.0µm in this case. 4) “Ni-14Al_RX_950_FA_DRX.pbfx” – a Pandat batch file to set up the simulation conditions including alloy chemistry, heat treatment schedule and output tables/graphs.

For model validations, all the simulations were performed in Pandat™ under a PanEvolution Project as shown in Figure 2. The first one is to simulate the dynamic recrystallization process by using the “Fast-Acting” model with the built-in nucleation model “DRX” and growth model “RX_Simplified”. The processing history is defined in .pbfx file as:

<processing_history useRate="true">

<node time="0" T="950" dT="0" EPS="0" dEPS="0.01"/>

<node time="260" T="0" dT="0" EPS="0" dEPS="0"/>

</processing_history>

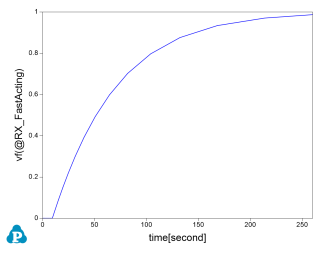

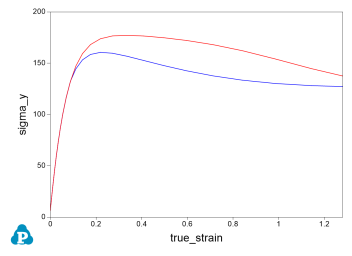

PanEvolution was designed to handle any arbitrary processing history. For demonstration, the processing condition is set to be 950 °C with strain rate at 0.01s-1. The simulation results are shown in Figure 3.

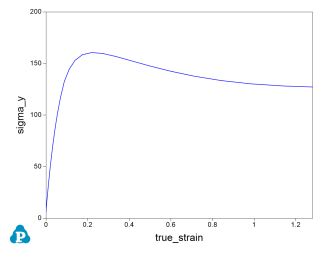

In order to run a user-defined growth model in KDB, another simulation was performed with the user-defined nucleation rate to overwrite the built-in model. In this case, a “<VariableTable>” sections is included in the KDB and the nucleation rate is defined by <Parameter type="Nucleation_Rate" value="0.1*(6.02e23/7.1E-6)^(2.0/3.0)/(max(1e-6, Grain_Size_0*2))*fv(@Grain)*strain_rate*exp(-224000/Rg/T)" description="user defined nucleation rate"/>.

In this case, the potential nucleation sites are less, and the nucleation of DRX is significantly lower and softening behavior due to DRX is also reduced as shown in Figure 4 (red color).